Advantage

- Servo motor from Panasonic and reducer from Shimpo. Adjusting and changing is more convenient, and the precision is much higher.

- No blister waste during break or stop.

- Data is storaged automatically in case of power failure or shut down.

- Ready packaged mould is more convenient for mould change, 30~40 minutes is enough.

- Output by conveying belt is more convenient for collection, and available to link cartoning machine.

Application:

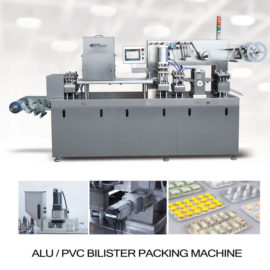

DPH-260H Automatic Blister packing Machine is our advanced equipment designed under updated improvement. It adopts the integral technology applying frequency inverter for speed control and mechanism, electricity, light and air to machine. Its design is in strict compliance with GMP standard and takes lead in the blister packer’s filed. Featuring advanced functions, ease in operation, high output, the machine is the most ideal packing equipment for large and medium size pharmaceutical enterprises, health food and food stuff trades

Features:

- Adopts top brand PLC controller with touch screen displayed in Chinese and English, Frequency inverter for speed control, servo traction, which can ensure the length of blister traction adjustable within the range.

- With thermal temperature control and test, main machine over loading protect, PVC and PTP packing material position test, feeder material position test, failure automatic debug and alarm, automatic protection and stop running.

- The machine station module type design of level frame, good sight, safe and convenient operation.

- Thermal with contact type, positive press formed, air cushion thermal seal upper and lower net, photo register make your product package better.

- PVC exchange support with bigger type material support, whole roller, which makes the equipment more practicability.

- The special design of moulds in rectangle shape, ladder type fixing, provide much convenience and ease to moulds replacement. All material contact parts adopt high quality stainless steel and aluminum metal, slap-up surface treatment craft.

- Discharging finished product in right order, automatic collection of bad products, auto rewinding of strap material to ensure easy collection.

- Feeding efficiently, reliable and suitable for many kinds type arrange and irregular feeding,(according to actual product design fit feeder).

- The machine has been designed into separated body, which is easily move into lifts or workshops.

| ITEM/MODEL | DPP-260H2 |

| Punching frequency | AL/Plastic 20-60times/min

AL/AL15-30times/min |

| Max forming depth | AL/Plastic 22mm

AL/AL 18mm (made to order) |

| Adjustable scope of Travel | made to order 30-140mm |

| Clean compressed air | Press0.6-0.8Mpa |

| Air consumer(air compressor) | ≥0.25m3/min(self prepared) |

| Power | 380V 50HZ 8.5Kw |

| Dimension | 4500x760x1620cm |

| Weight | 1800kg |